● Cleaning with high precision, streamer removal rate up to 99.9% after optimization, dust removal down to 30 ppm;

● Lower pellets carryover rate, no degradation of pellet particles:

● Full range of models, capacity from 30 kg/hour up to 100 ton/hour:

● The Spotlesser is compact in height and could be used in a wide range;

● High safety level, innovative open loop system with over 10 years of safe operation records in China;

● No electromagnetic/magnetic field radiation, no electric field radiation, Low noise level, fully compliance with HSE;

● Long term continuous operation;

● With complete knowhow and intellectual property right;

● Multiple featured option for customer's selection, tailor made as per specific requirements on site.

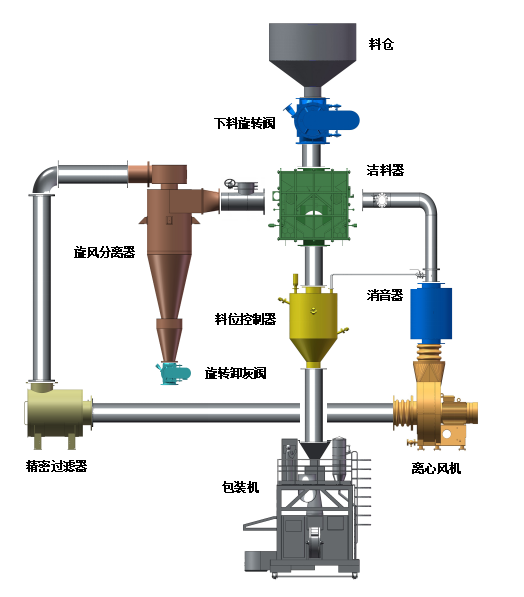

The SpotLesser pellets cleaning system could be operated in open loop and closed loop modes, the open loop mode is suitable for the cleaning of different material or changing of production line, it avoids the pollution problem in the same pellets. The filtrated air is supplied by the Blower fan. The induced fan indrafts the dusty air into the cyclone or dust collector. TCC are separated with air by dust collector and fall into dust bin, the purified air is discharged into atmosphere.

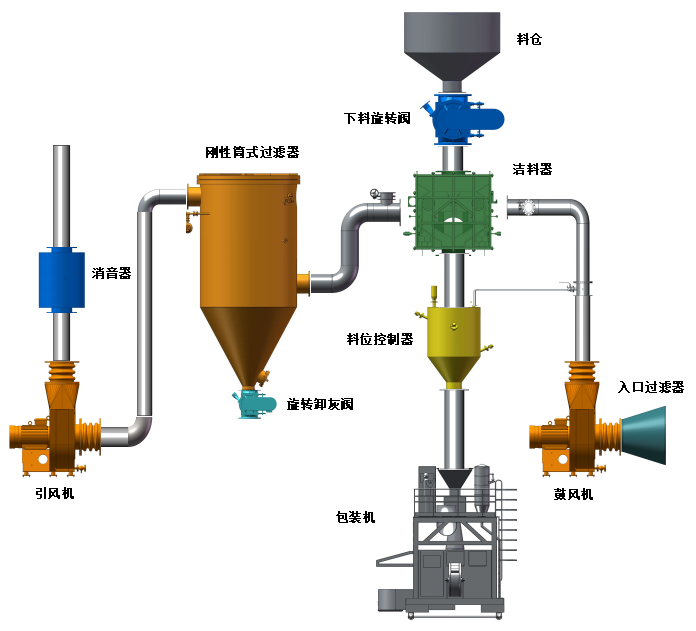

The close loop mode is suitable for standard and inertia gas applications. Fan provides fresh air to the Spotlcsscr pellet cleaning system. TCC are separated with air by dust collector and fall into dust bin, the purified air is discharged into atmosphere.